Siyakwamukela ukubonisana nokuxoxisana

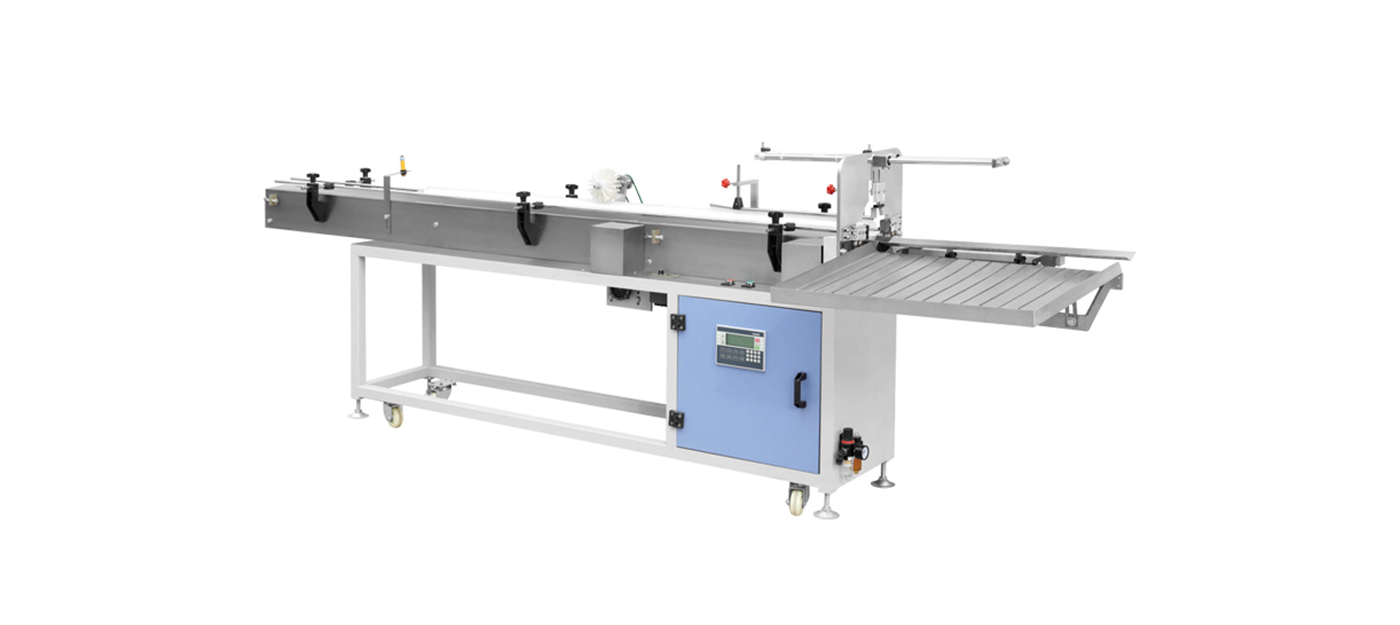

I-RM-4 Umshini Wokushisa Owenza Iziteshi ezine

Incazelo

Umshini we-4-station positive and negative pressure thermoforming umshini wokukhiqiza osebenza kahle ongasetshenziselwa ukukhiqiza amabhokisi ezithelo epulasitiki alahlwayo, izimbiza zezimbali, izivalo zenkomishi yekhofi nezivalo ezibuswe ngezimbobo, njll. Imishini ifakwe uhlelo olusheshayo lokushintsha isikhunta futhi inenzuzo yomklamo webhokisi lokufudumeza ngokwezifiso. Le mishini isebenzisa ubuchwepheshe be-thermoforming yengcindezi eqondile neyibi ukuze icubungule ishidi lepulasitiki libe sesimweni esidingekayo, usayizi kanye nomklamo wokubhoboza ohambisanayo ngokufudumeza ishidi lepulasitiki futhi ucindezele igesi yokucindezela enhle nebi. Lo mshini unamasethi amane ezindawo zokusebenza zokwakha, ukubhoboza izimbobo, ukubhoboza onqenqemeni, nokupakisha nokunamathisela, okungahlangabezana nezidingo zezimboni ezahlukene futhi kuqinisekiswe ikhwalithi nokuvumelana kwemikhiqizo.

Amapharamitha womshini

| Indawo yokubumba | Amandla okubamba | Isivinini sokugijima | Ukujiya kweshidi | Ubude bokwakha | Ukwakha ingcindezi | Izinto zokwakha |

| Ubukhulu. Isikhunta Ubukhulu | I-Clamping Force | Isivinini Somjikelezo Wokoma | Ubukhulu. Ishidi Ubukhulu | I-Max.Foming Ubude | I-Max.Air Ingcindezi | Impahla Efanelekayo |

| 820x620mm | 80T | 61/umjikelezo | 1.5mm | 100mm | 6 ibha | PP, PS, PET, CPET, OPS, PLA |

Izici

Ukulawula okuzenzakalelayo

Imishini yamukela uhlelo lokulawula oluzenzakalelayo oluthuthukisiwe, olungalawula ngokunembile imingcele efana nokushisa kokushisa, isikhathi sokubumba nokucindezela ukuze kuqinisekiswe ukuzinza nokuvumelana kwenqubo yokubumba.

Ukushintsha isikhunta ngokushesha

Umshini we-4-station thermoforming ufakwe uhlelo olusheshayo lokushintsha isikhunta, olwenza ushintsho olusheshayo lwesikhunta futhi luvumelane nezidingo zokukhiqiza zemikhiqizo ehlukene, ngaleyo ndlela ithuthukise ukuguquguquka kokukhiqiza.

Ukonga amandla

Imishini isebenzisa ubuchwepheshe obuthuthukisiwe bokonga amandla, okunciphisa ngempumelelo ukusetshenziswa kwamandla, ukunciphisa izindleko zokukhiqiza, futhi kulungele imvelo ngesikhathi esifanayo.

Kulula ukusebenza

Umshini we-4-station thermoforming ufakwe i-interface yokusebenza enembile, okulula ukuyisebenzisa futhi kulula ukuyifunda, ukunciphisa izindleko zokuqeqesha abasebenzi kanye namazinga amaphutha okukhiqiza.

Isicelo

Umshini we-4-station thermoforming usetshenziswa kabanzi embonini yokupakisha ukudla, futhi ufanelekile ikakhulukazi amabhizinisi akhiqiza imikhiqizo yepulasitiki ngesilinganiso esikhulu ngenxa yokusebenza kwayo okuphezulu, amandla aphezulu kanye nokuguquguquka.

Okokufundisa