I-RM 2RH Double Station IMC Thermoforming Machine

Amapharamitha womshini

| ◆Imodeli: | I-RM-2R |

| ◆Max.Indawo Eyakhayo: | 820*620mm |

| ◆Max.Forming Height: | 80mm |

| ◆Ubukhulu.Ubukhulu Beshidi(mm): | 2mm |

| ◆Max Air Pressure(Ibha): | 8 |

| ◆Dry Cycle Speed: | 48/cyl |

| ◆Claping Force: | 65T |

| ◆Amandla kagesi: | 380V |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Isinciphisi: | I-GNORD |

| ◆Uhlelo lokusebenza: | amathreyi, izitsha, amabhokisi, izivalo, njll. |

| ◆ Izingxenye Eziyinhloko: | PLC, Injini, Bearing, Gearbox, Motor, Gear, Pump |

| ◆Into Efanelekayo: | PP.PS.PET.CPET.OPS.PLA |

| Ubukhulu.Isikhunta Ubukhulu | I-Clamping Force | Isivinini Somjikelezo Wokoma | Ubukhulu.Ishidi Ubukhulu | I-Max.Foming Ubude | I-Max.Air Ingcindezi | Impahla Efanelekayo |

| 820x620mm | 85T | 48/umjikelezo | 2.8mm | 180mm | 8 ibha | PP, PS, PET, CPET, OPS, PLA |

Ividiyo Yomkhiqizo

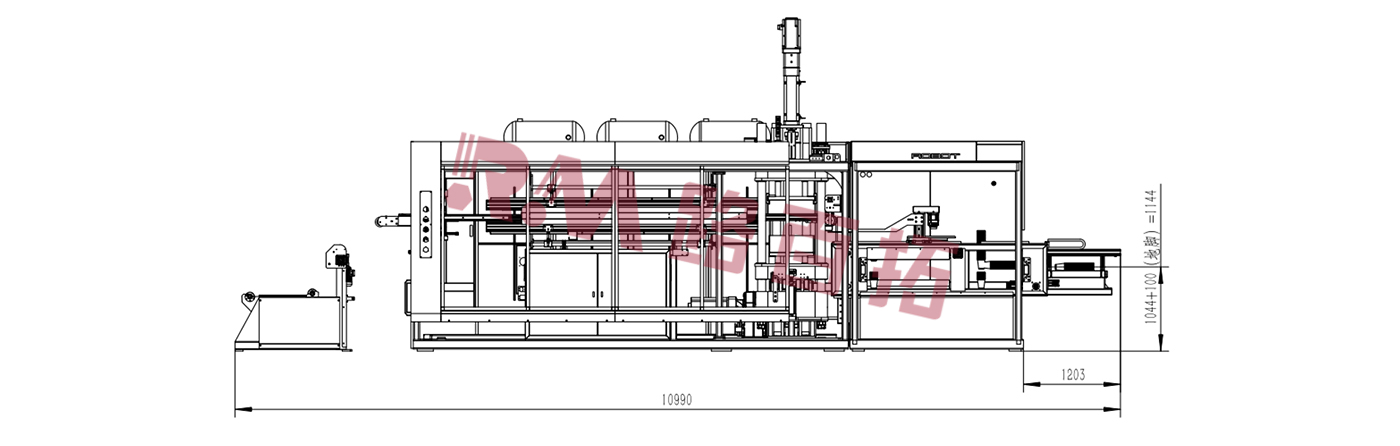

Umdwebo Womsebenzi

Izici Eziyinhloko

✦ Izwa izinga elisha lokukhiqiza ngomshini wethu wesimanje Wokwenza Nokusika Okuzenzakalelayo Okuzenzakalelayo Okusheshayo Okusheshayo.Ihambisana nomklamo weziteshi ezimbili, yenza ukwakha nokusika ngesikhathi esisodwa, ikhuphula kakhulu ukusebenza kahle kokukhiqiza.Isistimu yokusika i-in-die iqinisekisa ukusikeka okusheshayo nokunembayo, okwenza inqubo yokukhiqiza isebenze kahle.

✦Imodeli yethu inikezela ngamakhono okwenza ingcindezi eyakhayo nebi.Ngokusebenzisa ukushisa nokucindezela, ishidi lepulasitiki liguqulwa libe yisimo somkhiqizo oyifunayo.Ukwakhiwa kwengcindezi eqondile kuqinisekisa indawo yomkhiqizo ebushelelezi futhi engaguquki, kuyilapho ukwakheka kwengcindezi engemihle kuqinisekisa ukunemba kwezici ze-concave kanye ne-convex, okuholela kukhwalithi yomkhiqizo ezinzile futhi ephakeme.

✦Ifakwe uhlelo lwe-palletizing eku-inthanethi, umshini wethu uzuza ukupakishwa okuzenzakalelayo kwemikhiqizo eqediwe.Le nqubo yokupakisha eyenziwe lula ithuthukisa kakhulu ukusebenza kahle kokukhiqiza futhi inciphisa umfutho wabasebenzi, okuvumela iqembu lakho ukuthi ligxile kweminye imisebenzi ebalulekile.

✦Umshini wethu ukulungele kahle ukukhiqiza imikhiqizo enobude obuncane njengezinkomishi zesoso ezilahlwayo, amapuleti, nezivalo.Kodwa-ke, ingakwazi ukuzivumelanisa kalula nobukhulu bomkhiqizo obuhlukene kanye nokuma.Ngokumane uguqule isikhunta kanye nemingcele yokulungisa, kungenziwa izinhlobo eziningi zemikhiqizo.

✦ Faka imali ekusebenzeni kahle nangekhwalithi ngomshini wethu Wokwenza Nokusika Okuzenzakalelayo Okusheshayo Okusheshayo.Ukwakheka kanye nokusika ngesikhathi esisodwa, amandla okucindezela okuhle nokubi, ukunqwabelanisa okuzenzakalelayo, kanye nokuguquguquka ekukhiqizeni umkhiqizo - konke ngesixazululo esisodwa esinamandla.Hlala ngaphambi komncintiswano futhi uphakamise amandla akho okukhiqiza ngomshini wethu ophambili!

Indawo Yesicelo

Lo mshini we-2-station thermoforming usetshenziswa kakhulu ezimbonini zokupakisha ukudla nezimboni zokudla.Ngezinzuzo zayo nokuguquguquka, ihlinzeka amabhizinisi ngezixazululo zokukhiqiza ezisezingeni eliphezulu nezisebenza kahle kakhulu.

Okokufundisa

Isingeniso:

I-Thermoforming iyinqubo yokukhiqiza eguquguqukayo nesebenzayo esetshenziswa kuzo zonke izimboni ezahlukahlukene.Ukuqinisekisa ukukhiqizwa okungenamthungo kanye nekhwalithi ephezulu, ukulungiswa okufanele kwemishini, ukuphatha impahla eluhlaza, nokunakekelwa kubalulekile.

Ukulungiswa kwezisetshenziswa:

Ngaphambi kokuqala ukukhiqiza, qinisekisa uxhumo oluqinile namandla okunikezwa kwamandla omshini wakho we-2-station thermoforming.Yenza ukuhlola okuphelele kokushisisa, ukupholisa, amasistimu okucindezela, neminye imisebenzi ukuze uqinisekise ukusebenza kwakho okuvamile.Faka ngokuphephile isikhunta esidingekayo, uqinisekise ukuthi siqondaniswe ngokuphelele ukuze uvimbele noma yikuphi ukungahambi kahle okungenzeka ngesikhathi senqubo yokukhiqiza.

Ukulungiswa kwe-Raw Material:

Qala ngokukhetha ishidi lepulasitiki elifanele ukubunjwa, uqinisekise ukuthi lihambisana nezidingo eziqondile zephrojekthi.Naka kakhulu usayizi nokujiya, njengoba lezi zici zithinta kakhulu ubuqotho bomkhiqizo wokugcina.Ngephepha lepulasitiki elilungiselelwe kahle, ubeka isisekelo semiphumela ye-thermoforming engenasici.

Izilungiselelo Zokushisa:

Vula iphaneli yokulawula yomshini wakho we-thermoforming bese usetha izinga lokushisa lokushisa nesikhathi.Cabangela izici zezinto zepulasitiki kanye nezidingo zesikhunta lapho wenza lezi zinguquko.Vumela umshini we-thermoforming isikhathi esanele ukuze ufinyelele izinga lokushisa elibekiwe, uqinisekise ukuthi ishidi lepulasitiki lithola ukuthamba okufiswayo kanye nokulolongeka ukuze kubunjwe kahle.

Ukubumba - Ukupakisha :

Beka ngokucophelela ishidi lepulasitiki elishisiwe ngaphambili endaweni yesikhunta, uqinisekise ukuthi liphansi futhi libushelelezi.Qalisa inqubo yokubumba, unikeze amandla isikhunta ukuthi sisebenzise ingcindezi nokushisa phakathi nesikhathi esinqunyiwe, ulolonge ngobuciko ishidi lepulasitiki libe yifomu elifunayo.Ngemuva kokwakhiwa, vumela ipulasitiki iqine futhi iphole ngesikhunta, iqhubekele ekunqwabeni okuhlelekile okuhlelekile ukuze kufakwe i-palletizing ngempumelelo.

Khipha Umkhiqizo Ophelile:

Hlola ngokucophelela umkhiqizo ngamunye oqediwe ukuze uqiniseke ukuthi uhlangabezana nesimo esidingekayo futhi unamathela kumazinga aphezulu kakhulu.Lokhu kuhlola okucophelelayo kuqinisekisa ukuthi izinto ezidaliwe ezingenasici kuphela ezishiya umugqa wokukhiqiza, okuqinisa isithunzi sakho sokwenza kahle.

Ukuhlanza Nokunakekela:

Ukuze ulondoloze ukusebenza kahle kwemishini yakho ye-thermoforming, sebenzisa inqubo yokuhlanza nokunakekela ngenkuthalo.Ngemva kokusetshenziswa, vula umshini we-thermoforming bese uwunqamula emthonjeni wamandla.Yenza ukuhlanza ngokuphelele isikhunta kanye nezinto zokusebenza ukuze kuqedwe noma iyiphi ipulasitiki esele noma imfucumfucu.Hlola njalo izingxenye zemishini ehlukahlukene ukuze uqinisekise ukusebenza kwazo okuphelele, uvikele ukukhiqiza okungaphazamiseki.