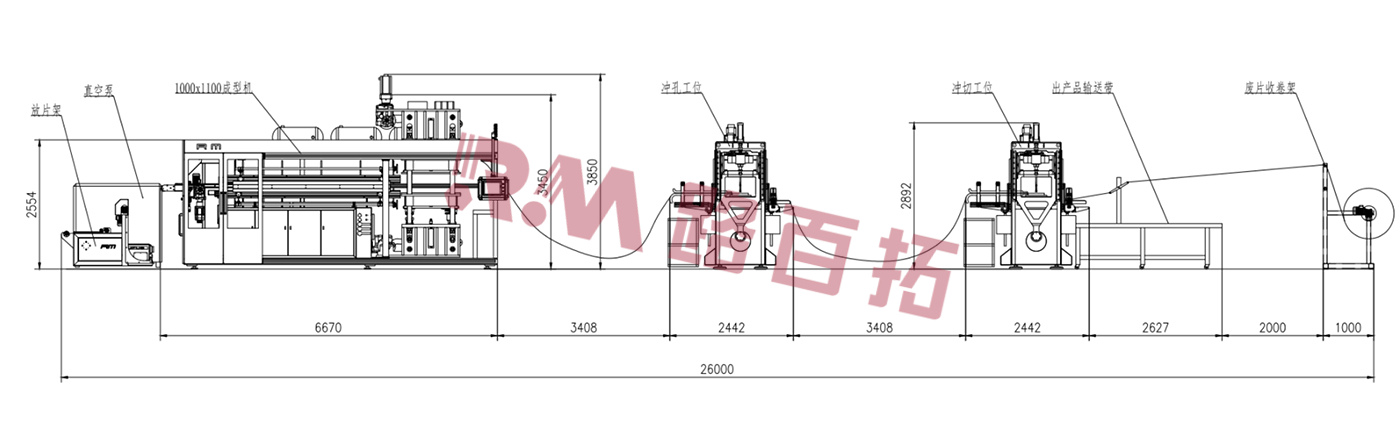

I-RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Amapharamitha womshini

| ◆Imodeli: | I-RM-T1011 |

| ◆Ubukhulu. usayizi wesikhunta: | 1100mm×1170mm |

| ◆Ubukhulu. indawo yokwakha: | 1000mm×1100mm |

| ◆Miz. Indawo yokwakha: | 560mm×600mm |

| ◆Ubukhulu. izinga lesivinini sokukhiqiza: | ≤25Times/min |

| ◆Max.Forming Height: | 150mm |

| ◆ Ububanzi beshidi(mm): | 560mm-1200mm |

| ◆Ibanga elihambayo lesikhunta: | I-stroke≤220mm |

| ◆Ubukhulu. i-clamping force: | ukwakha-50T, punching-7T kanye nokusika-7T |

| ◆Ukunikezwa kwamandla: | 300KW(amandla okushisa)+100KW(amandla okusebenza)=400kw |

| ◆Kuhlanganisa umshini wokubhoboza ongu-20kw, umshini wokusika ongu-30kw | |

| ◆Izicaciso zokunikezwa kwamandla: | AC380v50Hz,4P(100mm2)+1PE(35mm2) |

| ◆Isistimu yezintambo ezinhlanu ezinezintambo ezintathu | |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Isinciphisi: | I-GNORD |

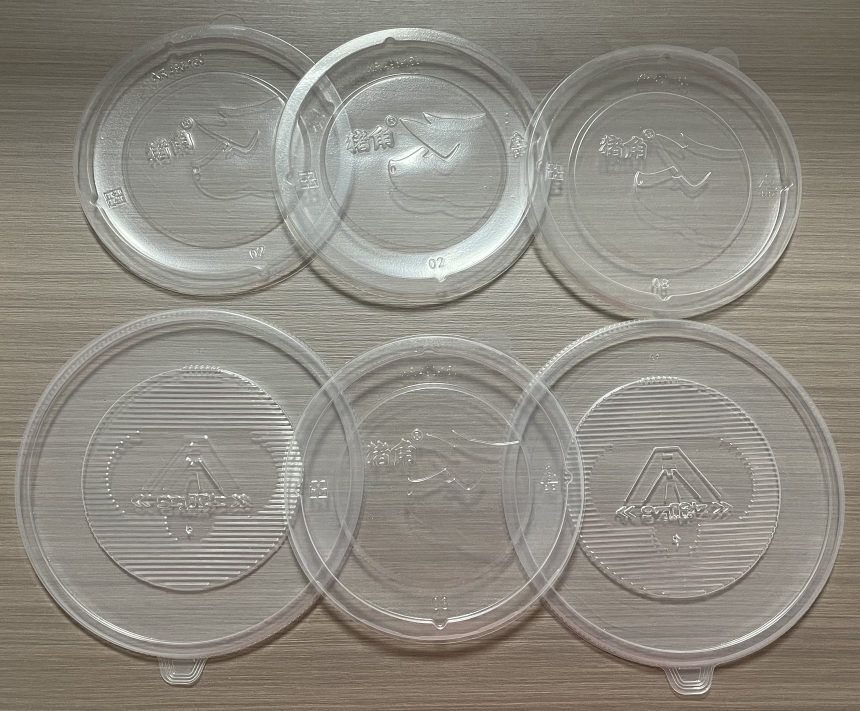

| ◆Uhlelo lokusebenza: | amathreyi, izitsha, amabhokisi, izivalo, njll. |

| ◆ Izingxenye Eziyinhloko: | PLC, Injini, Bearing, Gearbox, Motor, Gear, Pump |

| ◆Into Efanelekayo: | PP.PS.PET.CPET.OPS.PLA |

| Ubukhulu. Isikhunta Ubukhulu | I-Clamping Force | Ikhono lokubhoboza | Ukusika Amandla | Ubukhulu. Ukuphakama Kwakha | Ubukhulu. Umoya Ingcindezi | Isivinini Somjikelezo Wokoma | Ubukhulu. Ukubhoboza/ Ukusika Ubukhulu | Ubukhulu. Ukubhoboza/ Ukusika isivinini | Impahla Efanelekayo |

| 1000*1100mm | 50T | 7T | 7T | 150mm | 6 ibha | 35r/min | 1000*320 | 100 spm | PP, HI PS, PET, PS, PLA |

Ividiyo Yomkhiqizo

Umdwebo Womsebenzi

Izici Eziyinhloko

✦ Ukukhiqizwa okuphumelelayo: Umshini omkhulu we-thermoforming wefomethi wamukela indlela yokusebenza yomugqa wokukhiqiza oqhubekayo, ongaqedela ngokuqhubekayo nangempumelelo inqubo yokubumba yomkhiqizo. Ngohlelo lokulawula oluzenzakalelayo kanye nokusebenza komshini ngesivinini esikhulu, ukusebenza kahle kokukhiqiza kungathuthukiswa kakhulu ukuze kuhlangatshezwane nezidingo zokukhiqiza ngobuningi.

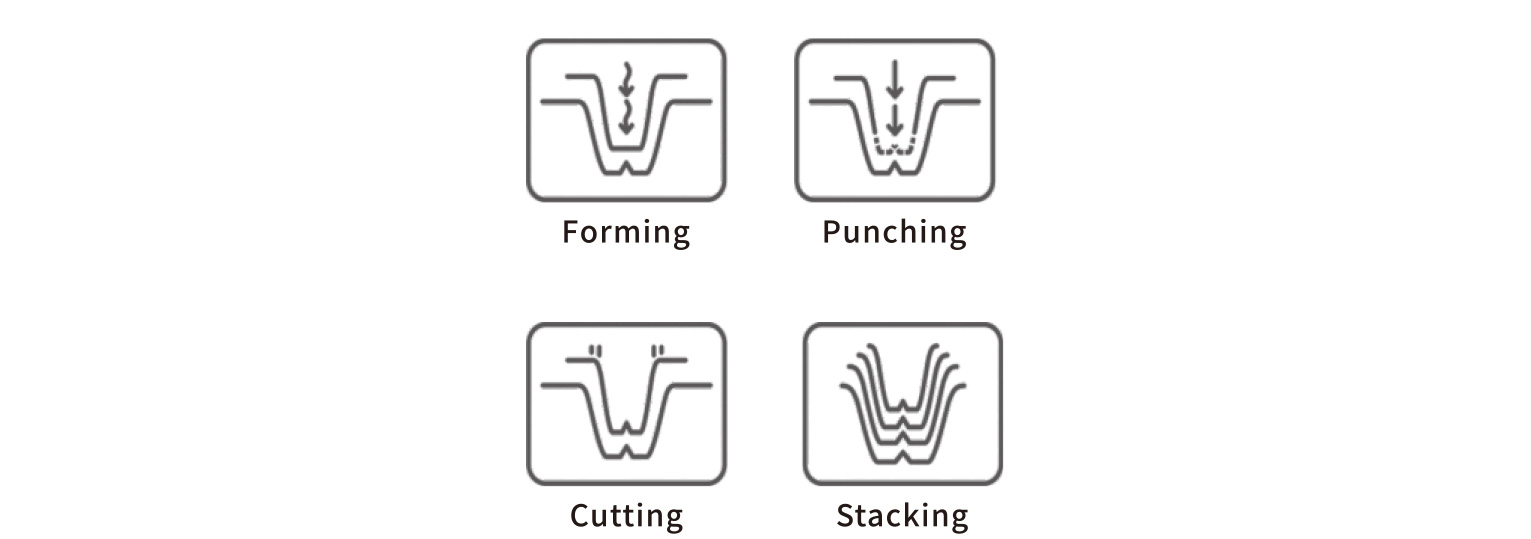

✦ Ukusebenza okuhlukahlukene: umshini unemisebenzi eminingi efana nokwakha, ukubhoboza, ukubhoboza emaphethelweni kanye nokunamathisela.

✦ Ukubumba okunembile kanye nemikhiqizo yekhwalithi ephezulu: Umshini we-thermoforming wefomethi enkulu usebenzisa ubuchwepheshe bokubumba obuphambili, obungakwazi ukulawula ngokunembile izinga lokushisa lokushisa, ingcindezi kanye nesikhathi sokushisa ukuze kuqinisekiswe ukuthi izinto zepulasitiki zincibilika ngokugcwele futhi zisakazwa ngokulinganayo ekubunjweni, ngaleyo ndlela ukhiqize imikhiqizo enekhwalithi ephezulu kanye nokunemba kobukhulu.

✦ Ukusebenza okuzenzakalelayo nokulawula okuhlakaniphile: Umshini ufakwe isistimu yokusebenza ezenzakalela kakhulu, ekwazi ukubona imisebenzi efana nokuphakela okuzenzakalelayo, ukwenza okuzenzakalelayo, ukubhoboza okuzenzakalelayo, ukubhoboza onqenqemeni okuzenzakalelayo kanye ne-automatic palletizing. Ukusebenza kulula futhi kulula, kunciphisa ukungenelela okwenziwa ngesandla, kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza nokunciphisa izindleko zokukhiqiza.

✦ Ukuphepha nokuvikelwa kwemvelo: Umshini omkhulu we-thermoforming wefomethi wenziwe ngezinto ezisezingeni eliphezulu, ezinokuqina okuhle nokuzinza. Iphinde ifakwe nohlelo lokuvikela ukuphepha ukuze kuqinisekiswe ukuphepha kwabaqhubi. Ngesikhathi esifanayo, umshini unomklamo wokonga amandla, onganciphisa ukusetshenziswa kwamandla futhi unciphise umthelela emvelweni.

Indawo Yesicelo

Umshini we-thermoforming wefomethi enkulu i-RM-T1011 umshini we-thermoforming usetshenziswa kabanzi embonini yezokuphekela, imboni yokupakisha ukudla kanye nemboni yempahla yasendlini. Ngenxa yokusebenza kahle kwayo okuphezulu, izici eziningi zokusebenza kanye nezici ezinembile, ingahlangabezana nezidingo zokukhiqiza zezimboni ezahlukene zemikhiqizo yepulasitiki futhi inikeze ukusekelwa okuqinile kwamabhizinisi ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Okokufundisa

Ukulungiswa kwezisetshenziswa:

Ukuze uqalise umshini wakho we-thermoforming, vikela umshini othembekile wefomethi enkulu ye-thermoforming ye-RM-T1011 ngokuqinisekisa ukuxhuma kwawo okuphephile nokuwuvula. Ukuhlola okuphelele kwamasistimu wokushisisa, ukupholisa, nokucindezela kubalulekile ukuze kuqinisekiswe ukusebenza kwawo okuvamile. Vikela inqubo yakho yokukhiqiza ngokufaka ngokucophelela isikhunta esidingekayo, uqinisekise ukuthi sibambelele ngokuqinile ekusebenzeni kahle.

Ukulungiswa kwe-Raw Material:

Ukuzuza ukuphelela ku-thermoforming kuqala ngokulungiselela ngokucophelela impahla eluhlaza. Khetha ngokucophelela ishidi lepulasitiki elifaneleka kangcono ukubunjwa, futhi uqinisekise ukuthi ubukhulu balo kanye nobukhulu balo buhambisana nezidingo ezithile zesikhunta. Ngokunaka le mininingwane, ubeka isiteji semikhiqizo yokugcina engenasici.

Izilungiselelo Zokushisa:

Vula amandla eqiniso wenqubo yakho ye-thermoforming ngokulungiselela ngobuchwepheshe izinga lokushisa lokushisa nesikhathi usebenzisa iphaneli yokulawula. Hlela izilungiselelo zakho ukuze zifane nezinto zepulasitiki nezimfuneko zesikhunta, uzuze imiphumela emihle.

Ukwakha - Ukubhoboza Izimbobo - Ukubhoboza Umphetho - Ukupakisha Nokunamathisela:

Beka kahle ishidi lepulasitiki elishisiwe ngaphambili endaweni yesikhunta, uqinisekise ukuthi liqondaniswe kahle futhi alinamibimbi noma ukuhlanekezela okungaphazamisa inqubo yokubunjwa.

Qalisa inqubo yokubumba, usebenzisa ngokucophelela ukucindezela nokushisa ngaphakathi kwesikhathi esibekiwe ukuze ulolonge ishidi lepulasitiki ngokunembile libe yifomu oyifunayo.

Uma ukwakheka sekuqediwe, umkhiqizo wepulasitiki osanda kwakheka uyekwa ukuze uqine futhi uphole ngaphakathi kwesikhunta, ngaphambi kokuqhubekela ekubhobozeni imbobo, ukubhoboza onqenqemeni, nokupakisha okuhlelekile ukuze kufakwe i-palletizing elula.

Khipha Umkhiqizo Ophelile:

Hlola umkhiqizo ngamunye oqediwe ngokucophelela ukuze uqiniseke ukuthi uhambisana nesimo esidingekayo futhi uthobela izindinganiso zekhwalithi ezimisiwe, wenze noma yiziphi izinguquko ezidingekayo njengoba kudingeka.

Ukuhlanza Nokunakekela:

Ngemva kokuqeda inqubo yokukhiqiza, vula umshini we-thermoforming futhi uwunqamule emthonjeni wamandla ukuze wonge amandla futhi ugcine ukuphepha.

Hlanza ngokuphelele isikhunta kanye nezinto zokusebenza ukuze ususe noma iyiphi ipulasitiki eyinsalela noma imfucumfucu, ulondoloze impilo ende yesikhunta futhi uvimbele ukukhubazeka okungenzeka emikhiqizweni yesikhathi esizayo.

Sebenzisa isimiso esivamile sokulungisa ukuze uhlole futhi usebenze izingxenye zemishini ehlukahlukene, uqinisekisa ukuthi umshini we-thermoforming uhlala usesimweni esikahle sokusebenza, uthuthukisa ukusebenza kahle nokuphila isikhathi eside ekukhiqizeni okuqhubekayo.